What kind of engine will propel your next car or truck? If you've been toying around with the idea of buying a diesel for its fuel economy (try nearly 50 mpg for the Volkswagen Jetta TDI), well, you may not need to give up on the trusted and familiar gasoline engine just yet.

That's because one of the technologies that makes diesels so miserly on fuel is coming to gasoline engines, too. It's called direct injection, and it refers to how the fuel makes its way inside an engine's controlled-explosion room, better known as a combustion chamber.

Advertisement

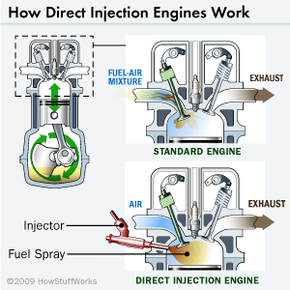

In a garden-variety gasoline engine with fuel injection, gasoline takes a more roundabout route than it does with the direct injection method. This indirect approach causes all manner of inefficiencies in burning the fuel, and it can result in a lot of usable energy getting wasted -- and you not getting the most for the money you spent at the pump.

In a direct injection engine, however, the fuel skips the waiting period it would have to endure inside a standard engine and instead proceeds straight to the combustion chamber. This allows the fuel to burn more evenly and thoroughly. For the driver, that can translate to better mileage and greater power to the wheels.

In the past, direct injection posed too many technical hurdles to make it worthwhile for mass market gasoline automobiles. But with advances in technology and greater pressure to make cars run more cleanly and efficiently, it looks as if gasoline direct injection -- or GDI as it's referred to in industry lingo -- is here to stay. In fact, most of the major car manufacturers make or plan to soon introduce gasoline cars that take advantage of this fuel saving and performance enhancing system.

Read on learn about the nuts and bolts -- and pistons and valves -- of direct injection.