For over a hundred years, engines got bigger, faster, and meaner, with more horsepower and torque. Exhaust belched from the tailpipes like a dragon awoken from its slumber to roar at potential thieves of its treasure. At least, that's what the guy with the wide tires and the airbrushed flame job wants you to think.

Then came the twentieth century, when we realized that fire-breathing engines were slaying more than red-light drag racing opponents. Turns out, all that belching was changing the climate and creating nasty smog. Too many dragons were making the planet more like Mordor than the Shire.

Advertisement

Who can save us from these exhaust-belching dragons? Who can tame their gas-guzzling ways with his sword of science and engineering? Who carries the one true ring of fuel efficiency? One man: James Atkinson of Hampstead, Middlesex, England. Also of 1887.

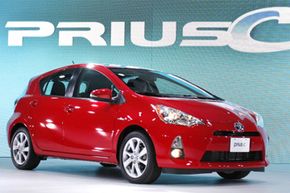

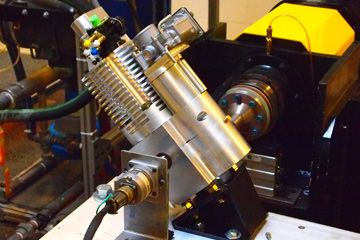

That's right -- the latest in green engine technology comes from the dawn of the automotive age. The Atkinson cycle engine was patented in the United States in 1887 (Atkinson filed for U.K. and European patents a couple years earlier). But the uneven strokes of the piston in his gasoline-powered combustion engine fit our modern hybrid systems pretty neatly.

The Atkinson cycle engine used in so many hybrids these days works on the same principle as the original -- with the obvious advantage of a century of technological advances. But in order to understand where we're at today, we first have to know where we've been. Set your time machine for 1887!

Advertisement