What if you were told that someday, your car could have a one-cylinder engine under its hood that has 100 horsepower, gets 100 miles per gallon (42.5 kilometers per liter), and can run on any type of fuel?

Odds are, you'd probably think that's something out of a science fiction movie, or that it's some kind of far-flung concept that's still decades away from reality.

Advertisement

Not so, according to Matthew Riley, the CEO and chief research scientist at Kansas-based Grail Engine Technologies. He says that his company's two-stroke Grail Engine could be in consumers' cars within two to five years. In February 2012, after three years of development, the company established their first working prototype, and big car companies like Honda and Ford have already shown interest.

Riley says the Grail Engine could be 50 percent cheaper to build while boasting 30 percent better fuel economy over current engines, and it's flexible about what fuel it runs on. It has a wide variety of possible applications, he said. It also doesn't have the pollution and reliability problems seen in most other two-stroke engines.

"It's going to change the way things work," said Riley, a scientist with more than 20 years of experience developing experimental engines. "The idea comes from the thought that there has to be a better way to make two-strokes because they're better performing."

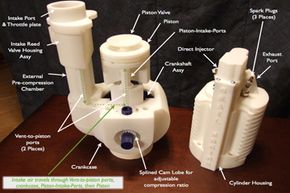

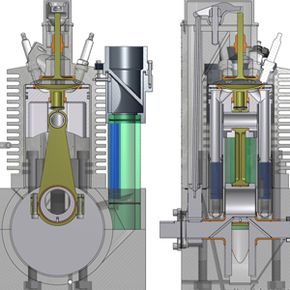

What makes the Grail Engine so amazing? Interestingly enough, it doesn't rely on a single breakthrough technology to get the job done. The engine takes a variety of current, cutting-edge engine technologies and puts them all together in one package. "It's all proven technology that's been used in the past," Riley said.

In essence, it's a very high-tech two-stroke engine that uses forced induction, direct injection and other technologies for impressive power and efficiency. It's also a pioneer in what the company calls "semi-homogeneous charged compression ignition." We'll cover what all of that means in a little bit.

In this article, we'll learn all about how the Grail Engine works, and explore how it could be put to use in the very near future.

Advertisement