In 2006, the United States consumed an average of almost 20.6 million barrels of petroleum per day, the equivalent of more than 865 million gallons of oil [source: Energy Information Administration]. Oil powers your car on a trip to the grocery store. It helps industry develop and fosters technological advances in science and medicine. It also creates a tremendous amount of wealth: The global economy is based in large part on oil drilling, refining, transportation and distribution.

Advertisement

But oil is a finite resource produced from the fossilized remains of ancient marine plants and animals. It takes at least 10 million years for fossilized remains to become crude oil, and people use oil much faster than it is created. Eventually oil production will peak, and we will begin to run out. Some estimate that this peak has already occurred; others see it taking place in the near future. Either way, most people believe that we are in the midst of an impending energy crisis. After all, petroleum plays such a big role in daily human activity. What happens when we run out of oil?

The energy sector spends billions on the quest for alternatives to gasoline. But the next energy source has to do more than just supply the world with power. With increasing concerns over greenhouse gases (GHGs) from fossil fuels leading to global warming, the next fuel has to be clean, too. It has to be affordable, and it has to help sustain the economy.

The next generation of fuels needs to arrive quickly, to help people transition from petroleum. After all, the world can't grind to a halt for a decade or two while the next fuel is developed and implemented.

All of this put together sounds like an impossible laundry list of demands on any fuel source. That's why it's so surprising that, after a just a few years of research, an energy source that seems to fulfill all of these obligations is emerging.

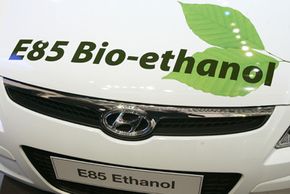

Ethanol (ethyl alcohol) is a form of fuel derived from the complex carbohydrates in plants. For decades, researchers have been aware of its potential as a fuel. But the process to produce ethanol inexpensively and efficiently has been elusive -- until now, some scientists say.

A fast-growing grass known as switchgrass can be found around the United States, Canada, Central and South America, and parts of Africa. And, if it continues to show the kind of promise it does now, it may be what you use to fuel your car in the next 20 years. So how can grass become fuel? Read the next page to find out about the sunny forecast for switchgrass as an answer to the impending energy crisis.

Advertisement