With each passing day, there are more and more people asking, "what is biodiesel?" Even in your daily routines, there's a good chance of someone mentioning it. And it's easy to understand why.

Whether it's in automotives, economics, history, geography or politics, oil has managed to filter into almost every aspect of our daily lives. It's one of the most discussed (and controversial) commodities that consumers rely on daily.

Advertisement

As such, any increase in the cost of oil sparks even more interest in gasoline alternatives. Things like electric cars and hydrogen fuel cells are being talked about as feasible alternatives to oil.

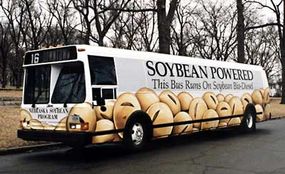

But, not lost in the mix are the biofuels, fuels made from biological ingredients instead of fossil fuels. These starting ingredients can range from waste vegetable oil to soybeans to animal fat, depending on the type of fuel being made and the production method.

In this article, we'll take a closer look at biodiesel, one of the major biofuels. For starters, it would be a good idea to check out How Car Engines Work and How Diesel Engines Work to get some background. After that, head back over and we'll separate biodiesel fact from fiction.

Generally speaking, biodiesel is an alternative or additive to standard diesel fuel that is made from biological ingredients instead of petroleum (or crude oil). Biodiesel is usually made from plant oils or animal fat through a series of chemical reactions. It is both non-toxic and renewable. Because biodiesel essentially comes from plants and animals, the sources can be replenished through farming and recycling.

Biodiesel is safe and can be used in modern diesel engines with little or no modification needed. Although biodiesel can be used in its pure form, it is usually blended with standard petroleum diesel fuel. Blends are indicated by the abbreviation Bxx, where xx is the percentage of biodiesel in the mixture. For example, the most common blend is B20, or 20 percent biodiesel to 80 percent standard. So, B100 refers to pure biodiesel [source: U.S. Department of Energy].

Biodiesel isn't just a catch-all term, however. There is also a formal, technical definition that is recognized by ASTM International (known formerly as the American Society for Testing and Materials), the organization responsible for providing industry standards. According to the National Biodiesel Board (NBB), the technical definition of biodiesel is as follows:

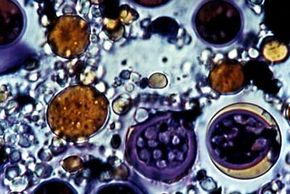

- a fuel comprised of mono-alkyl esters of long chain fatty acids derived from vegetable oils or animal fats, designated B100, and meeting the requirements of ASTM D 6751.

That sounds kind of rough, but it's a lot more familiar than you may think — you encounter these fatty acids every day. We'll look at them in more detail in the next section.

Advertisement