Internal combustion engines pollute the air. Internal combustion engines rob the planet of precious and non-renewable resources. Internal combustion engines require fossil fuels that tie the United States economically to countries that we'd rather not be doing business with.

And internal combustion engines aren't going away anytime soon.

Advertisement

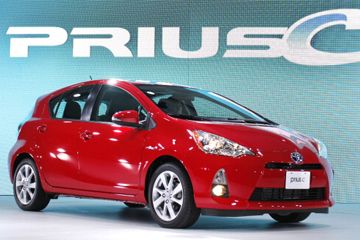

Oh, sure, you've heard about all the new technologies that should be replacing the internal combustion engine any day now, technologies like electric motors, hybrid power trains, hydrogen fuel cells and even cars that run on compressed air, but none of these technologies is ready to save the auto industry from the internal combustion engine quite yet. Electric motors are probably our best bet for the immediate future and there are even some cars on the market now that use them as a power source, but they take time to recharge, have a limited driving range, and they can't simply be fueled up in five minutes at the local service station. Besides, do you really want to get stuck in the middle of East Nowhere, Middle America, with a dead lithium-ion battery array and nobody around who has the foggiest notion how to recharge it? Hybrid power trains are already quite feasible, as the huge success of the Toyota Prius demonstrates, but they still contain internal combustion engines, so they don't really solve the problem. They just postpone the day when we'll finally need to get rid of this antiquated technology. Hydrogen fuel cell cars will be really amazing when they're available in vehicles that can be bought and driven by the average consumer. This should be, oh, about 20 to 30 years from now, around the time you'll invest in your first set of false teeth. And compressed air cars? Nobody really knows when those will be ready to hit the road, but it'll probably be a good while yet before you can refuel your car using a bicycle pump.

These technologies are important. Think tanks and auto manufacturers are researching them right now. The transportation your children's children use will depend on them. Someday one or all of these technologies will free the world from its out-of-control addiction to fossil fuels. But in the meantime what we really need is something that can realistically be ready for practical use within the next few years: a better internal combustion engine.

Here's the good news: Better internal combustion engines are on the way. And when we say better we mean lighter, more fuel efficient and less polluting. If we can't put internal combustion engines out to pasture quite yet, we can at least make them behave a little more politely while they're still galloping around on the public streets.

One of the most exciting new types of internal combustion engines is the opposed-piston opposed-cylinder engine, and if you can't remember all those tongue-twisting syllables you can just call it an OPOC engine. (Don't feel bad. Everybody else calls it that too.) OPOC engines aren't really new -- the idea's been around for a while -- but a company called Ecomotor is finally getting serious about building OPOCs that will be ready for consumer vehicles long before hydrogen fuel cells are the rage of the nation. And as proof that Ecomotors is offering serious technology that really could revolutionize the way we use gasoline in the near future, a fellow named Bill Gates has already invested in the company. Yes, that Bill Gates, and nobody can say that the co-founder of Microsoft doesn't know a thing or two about the practical aspects of cutting-edge technology.

But what exactly is an OPOC engine and how does it differ from the internal combustion engines that all of us love and hate? To answer that question, we'll first give you a refresher course in standard car engines, and then we'll show you how OPOCs do pretty much the same thing but just a little differently -- and a little better.

Advertisement