If you have a few soda cans and a few other easy-to-find accessories, you can recreate one of the first commercially viable engines ever made. Though small in size, a Coke can Stirling engine still speaks to our collective mechanical soul as it chuffs and chunks away on a shelf, rotating a flywheel, spinning a few fan blades, or even generating a few watts.

Its very simplicity evokes a different time. And whether looked at as a proof of concept, an interesting model, a conversation piece or a piece of kinetic sculpture, making a soda can Stirling engine is a great way to step into the past.

Advertisement

The Stirling engine was the brain child of Robert Stirling, who invented the concept in 1816. The idea behind his engine was to use air to power an engine, rather than the up-and-coming technology at the time -- steam.

What set Stirling's engine apart from other was the use of an "economizer," which enhanced fuel economy. This is now known as a regenerator. Between 1816 and 1843 Stirling and his brother, James, refined the engine's design and efficiency. By mid-19th century his engines were powering major industries including foundries. However, his engine, as well as most hot air engines, was more suited to low-power applications. His desire to create a safer alternative to the oft-exploding steam engines was defeated by the need for more power to run growing industries.

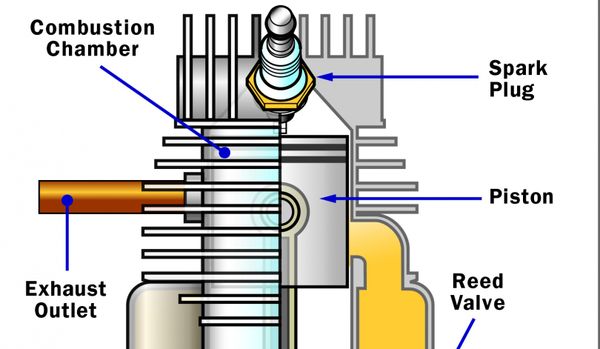

The first thing you should know about a Stirling engine is how the parts go together, and how they work.

Advertisement