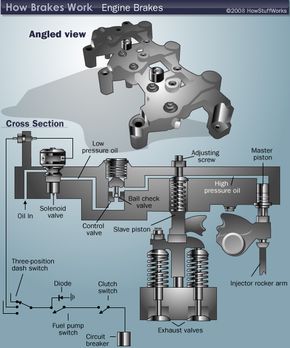

You either love it or hate it: The sound of a big rig hitting the brakes. The rumbling sound may be familiar, but what exactly is going on in there? Engine brakes are used in heavy duty and commercial vehicles -- like semitrailers and buses -- to increase speed control. Engine brakes are commonly known as Jake brakes because the largest manufacturer is Jacobs Vehicle Systems [source: Jacobs Vehicle Systems].

Braking causes friction, which in turn causes heat. (Read How Brakes Work to get a better understanding of the process.) Too much heat, like what is produced when a big rig tries to maintain speed and control on steep downhill grades, can cause brakes to overheat and fail. Downshifting the transmission on steep grades helps passenger vehicles more than big rigs due to the substantial weight difference.

Advertisement

Engine brakes reduce the occurrence of brake failure by using the engine to slow the rig. They increase the effectiveness of braking, save money by reducing wear and tear on the tires and brake system, and increase safety.

Though engine brakes are a very important component to maintaining safety on the open road, they are often met with opposition in populated areas. And signs prohibiting their use can be found all across the country.

In this article, we'll discuss the inner workings of engine brakes, exhaust brakes and current legislation about this controversial topic.