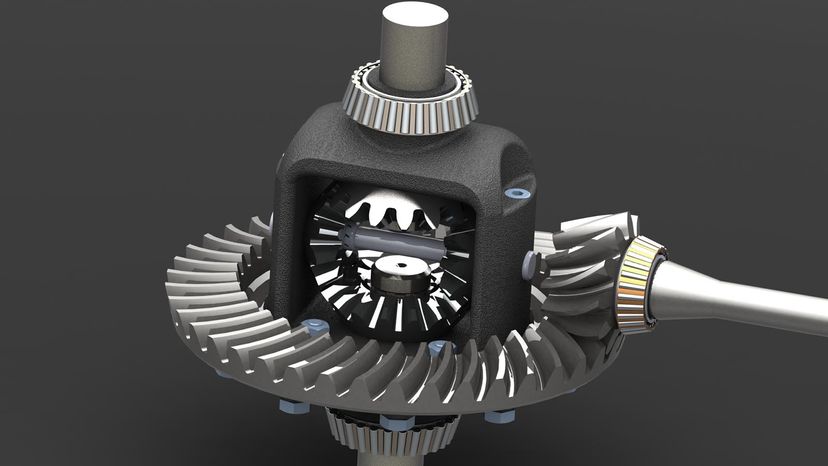

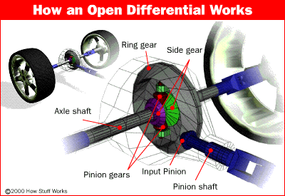

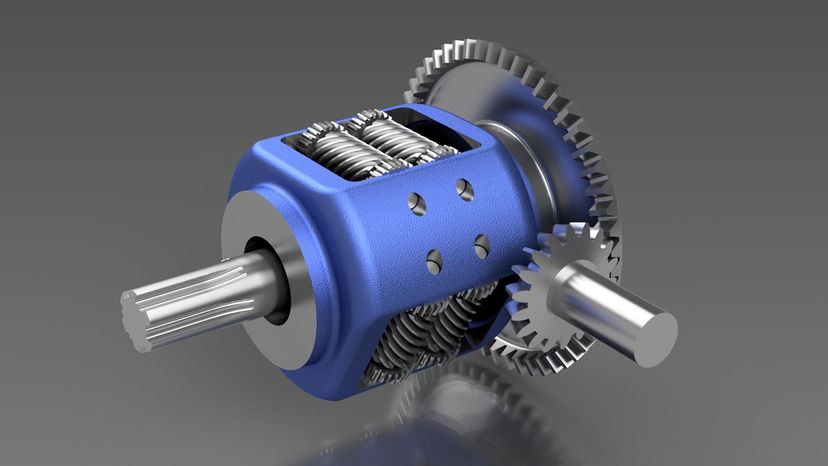

A differential is a mechanism that takes in energy on its input side and then splits that energy on two output sides. This is particularly useful in automotive applications because it converts the rotational force of an engine into the torque that drives the wheels.

The differential also lets each of the drive wheels spin at different speeds, which is important for smooth cornering.

Advertisement

The car differential has three jobs:

- To aim the engine power at the wheels

- To act as the final gear reduction in the vehicle, slowing the rotational speed of the transmission one final time before it hits the wheels

- To transmit the power to the wheels while allowing them to rotate at different speeds

Why Your Car Needs a Differential

Car wheels spin at different speeds, especially when they're turning. Since speed is equal to the distance traveled divided by the time it takes to go that distance, the wheels that travel a shorter distance travel at a lower speed.

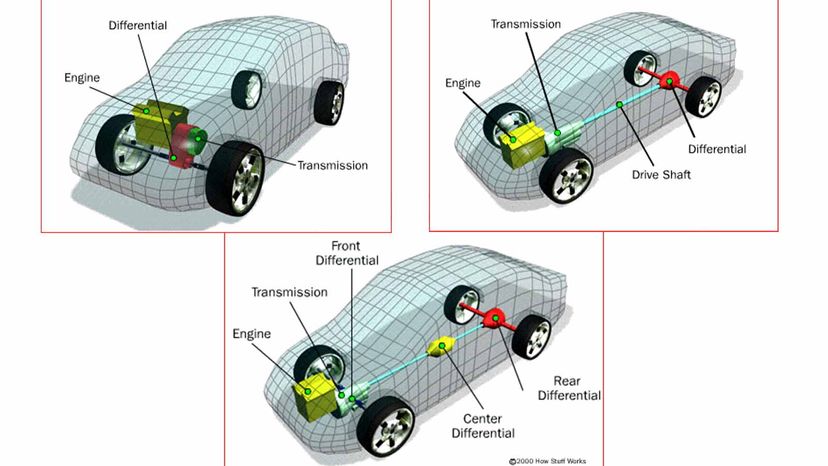

For the non-driven wheels on your car — the front wheels on a rear-wheel drive car and the back wheels on a front-wheel drive car — this is not an issue. There is no connection between them, so they spin independently.

But the driven wheels are linked together so that a single engine and transmission can turn both wheels. If your car did not have a differential, the wheels would have to be locked together, forced to spin at the same speed. This would make turning difficult and hard on your car. For the car to be able to turn, one tire would have to slip.

With modern tires and concrete roads, a great deal of force is required to make a tire slip. That force would have to be transmitted through the axle from one wheel to another, putting a heavy strain on the axle components.

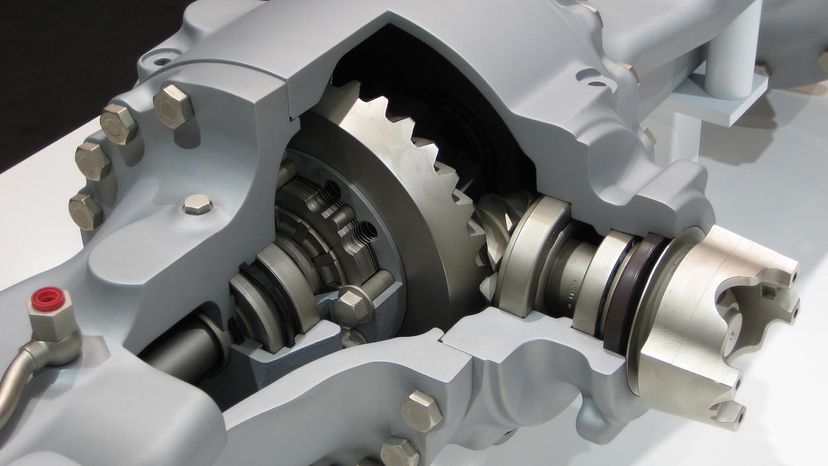

Like engines and transmissions, differentials need lubricating fluid to operate. This oil should be checked and occasionally replaced during automotive maintenance.

In this article, you'll learn why your car needs a differential, how it works and what its shortcomings are. We'll also look at several types of positraction, also known as limited slip differentials.