James Bond has them, Hummers have them, most truckers have them and the military has had them for years. Self-inflating tires allow a vehicle to adjust to the current terrain for ideal performance and safety in those conditions.

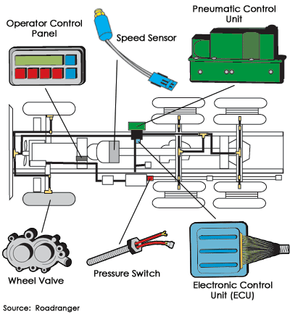

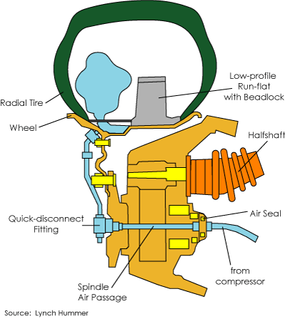

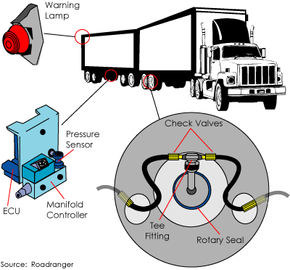

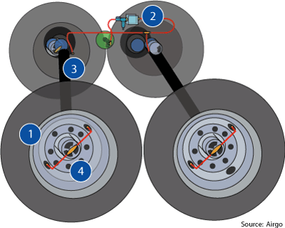

Currently, lots of consumer vehicles are equipped with pressure-monitoring systems, but there's no way for the driver to do anything about it without an external air source. There are lots of self-inflating-tire systems on the market, but most of them are only available for commercial and military applications. The exception, of course, is the CTIS system on the Hummer.

Advertisement

In this article, we're going to learn about some of the tire-inflation systems out there and see when there might be one on the market for us regular people who drive regular cars.

According to AAA, about 80 percent of the cars on the road are driving with one or more tires underinflated. Tires lose air through normal driving (especially after hitting pot holes or curbs), permeation and seasonal changes in temperature. They can lose one or two psi (pounds per square inch) each month in the winter and even more in the summer. And, you can't tell if they're properly inflated just by looking at them. You have to use a tire-pressure gauge. Not only is underinflation bad for your tires, but it's also bad for your gas mileage, affects the way your car handles and is generally unsafe.

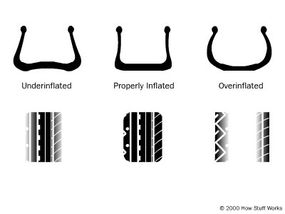

When tires are underinflated, the tread wears more quickly. According to Goodyear, this equates to 15 percent fewer miles you can drive on them for every 20 percent that they're underinflated. Underinflated tires also overheat more quickly than properly inflated tires, which causes more tire damage. The faded areas below indicate areas of excessive tread wear.

Because tires are flexible, they flatten at the bottom when they roll. This contact patch rebounds to its original shape once it is no longer in contact with the ground. This rebound creates a wave of motion along with some friction. When there is less air in the tire, that wave is larger and the friction created is greater -- and friction creates heat. If enough heat is generated, the rubber that holds the tire's cords together begin to melt and the tire fails. See How Tires Work to learn more.

Because of the extra resistance an underinflated tire has when it rolls, your car's engine has to work harder. AAA statistics show that tires that are underinflated by as little as 2 psi reduce fuel efficiency by 10 percent. Over a year of driving, that can amount to several hundred dollars in extra gas purchases.