Key Takeaways

- Stirling engines operate using a closed cycle that contains a fixed amount of gas. The Stirling cycle consists of four main processes driven by external heat and cooling sources.

- The process involves heating and cooling gas in separate chambers connected by pistons. This causes the gas to expand and contract, moving the pistons and creating mechanical work.

- Improving the efficiency of a Stirling engine entails increasing the temperature during the heating stage to raise the pressure and optimizing the cooling stage to decrease the pressure, effectively boosting the engine's power output.

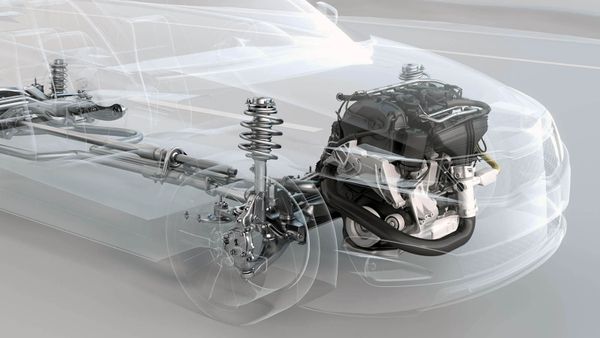

The Stirling engine is a heat engine that is vastly different from the internal-combustion engine in your car. Invented by Robert Stirling in 1816, the Stirling engine has the potential to be much more efficient than a gasoline or diesel engine. But today, Stirling engines are used only in some very specialized applications, like in submarines or auxiliary power generators for yachts, where quiet operation is important. Although there hasn't been a successful mass-market application for the Stirling engine, some very high-power inventors are working on it.

A Stirling engine uses the Stirling cycle, which is unlike the cycles used in internal-combustion engines.

Advertisement

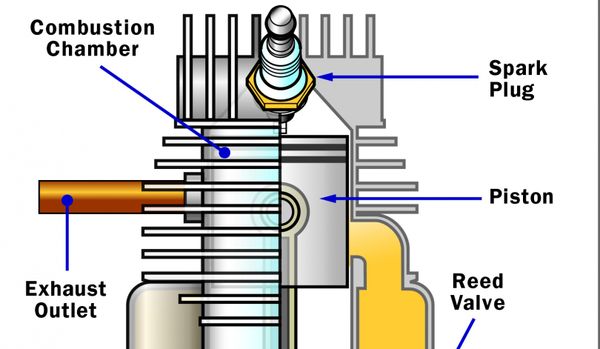

- The gasses used inside a Stirling engine never leave the engine. There are no exhaust valves that vent high-pressure gasses, as in a gasoline or diesel engine, and there are no explosions taking place. Because of this, Stirling engines are very quiet.

- The Stirling cycle uses an external heat source, which could be anything from gasoline to solar energy to the heat produced by decaying plants. No combustion takes place inside the cylinders of the engine.

There are hundreds of ways to put together a Stirling engine. In this article, we'll learn about the Stirling cycle and see how two different configurations of this engine work.

Advertisement