If you read How Two-stroke Engines Work, you learned that one big difference between two-stroke and four-stroke engines is the amount of power the engine can produce. The spark plug fires twice as often in a two-stroke engine -- once per every revolution of the crankshaft, versus once for every two revolutions in a four-stroke engine. This means that a two-stroke engine has the potential to produce twice as much power as a four-stroke engine of the same size.

The two-stroke engine article also explains that the gasoline engine cycle, where gas and air are mixed and compressed together, is not really a perfect match for the two-stroke approach. The problem is that some unburned fuel leaks out each time the cylinder is recharged with the air-fuel mixture. (See How Two-stroke Engines Work for details.)

It turns out that the diesel approach, which compresses only air and then injects the fuel directly into the compressed air, is a much better match with the two-stroke cycle. Many manufacturers of large diesel engines therefore use this approach to create high-power engines.

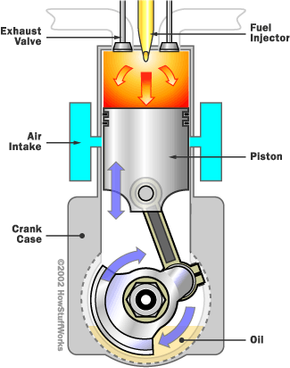

The figure shows the layout of a typical two-stroke diesel engine:

At the top of the cylinder are typically two or four exhaust valves that all open at the same time. There is also the diesel fuel injector (shown above in yellow). The piston is elongated, as in a gasoline two-stroke engine, so that it can act as the intake valve. At the bottom of the piston's travel, the piston uncovers the ports for air intake. The intake air is pressurized by a turbocharger or a supercharger (light blue). The crankcase is sealed and contains oil as in a four-stroke engine.

The two-stroke diesel cycle goes like this:

- When the piston is at the top of its travel, the cylinder contains a charge of highly compressed air. Diesel fuel is sprayed into the cylinder by the injector and immediately ignites because of the heat and pressure inside the cylinder. This is the same process described in How Diesel Engines Work.

- The pressure created by the combustion of the fuel drives the piston downward. This is the power stroke.

- As the piston nears the bottom of its stroke, all of the exhaust valves open. Exhaust gases rush out of the cylinder, relieving the pressure.

- As the piston bottoms out, it uncovers the air intake ports. Pressurized air fills the cylinder, forcing out the remainder of the exhaust gases.

- The exhaust valves close and the piston starts traveling back upward, re-covering the intake ports and compressing the fresh charge of air. This is the compression stroke.

- As the piston nears the top of the cylinder, the cycle repeats with step 1.

From this description, you can see the big difference between a diesel two-stroke engine and a gasoline two-stroke engine: In the diesel version, only air fills the cylinder, rather than gas and air mixed together. This means that a diesel two-stroke engine suffers from none of the environmental problems that plague a gasoline two-stroke engine. On the other hand, a diesel two-stroke engine must have a turbocharger or a supercharger, and this means that you will never find a diesel two-stroke on a chain saw -- it would simply be too expensive.