Most people know that cars come with two basic transmission types: manuals, which require that the driver change gears by depressing a clutch pedal and using a stick shift, and automatics, which do all of the shifting work for drivers using clutches, a torque converter and sets of planetary gears. But there's also something in between that offers the best of both worlds -- the dual-clutch transmission, also called the semi-automatic transmission, the "clutchless" manual transmission and the automated manual transmission.

In the world of racecars, semi-automatic transmissions, such as the sequential manual gearbox (or SMG), have been a staple for years. But in the world of production vehicles, it's a relatively new technology -- one that is being defined by a very specific design known as the dual-clutch, or direct-shift, gearbox.

Advertisement

This article will explore how a dual-clutch transmission works, how it compares to other types of transmissions and why some predict that it is the transmission of the future.

Hands-On or Hands-Off

A dual-clutch transmission offers the function of two manual gearboxes in one. To understand what this means, it's helpful to review how a conventional manual gearbox works. When a driver wants to change from one gear to another in a standard stick-shift car, he first presses down the clutch pedal. This operates a single clutch, which disconnects the engine from the gearbox and interrupts power flow to the transmission. Then the driver uses the stick shift to select a new gear, a process that involves moving a toothed collar from one gear wheel to another gear wheel of a different size. Devices called synchronizers match the gears before they are engaged to prevent grinding. Once the new gear is engaged, the driver releases the clutch pedal, which re-connects the engine to the gearbox and transmits power to the wheels.

So, in a conventional manual transmission, there is not a continuous flow of power from the engine to the wheels. Instead, power delivery changes from on to off to on during gearshift, causing a phenomenon known as "shift shock" or "torque interrupt." For an unskilled driver, this can result in passengers being thrown forward and back again as gears are changed.

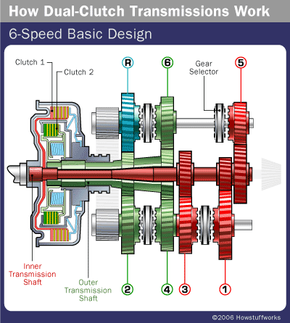

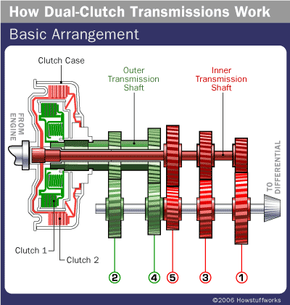

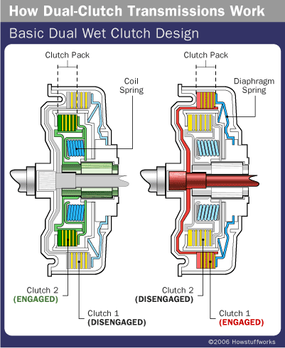

A dual-clutch gearbox, by contrast, uses two clutches, but has no clutch pedal. Sophisticated electronics and hydraulics control the clutches, just as they do in a standard automatic transmission. In a DCT, however, the clutches operate independently. One clutch controls the odd gears (first, third, fifth and reverse), while the other controls the even gears (second, fourth and sixth). Using this arrangement, gears can be changed without interrupting the power flow from the engine to the transmission. Sequentially, it works like this:

Advertisement