How Does a Crusher Crush?

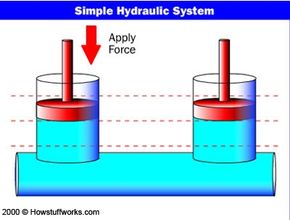

Almost all modern car crushers use a hydraulic press to crush the cars. A large motor powers a pump that pushes hydraulic fluid to drive large cylinders. Using principles of force-multiplication, a hydraulic system can generate over 2,000 psi and impart more than 150 tons of crushing force onto a pile of scrap cars. For more details on hydraulic systems, read How Hydraulics Work.

- bed where all the cars are loaded.

- A crushing plate rises to make room for the cars, and then drops to apply the crushing power.

- The engine, pump, valves, tubing and other parts of the hydraulic system.

- Guideposts that align the crushing plate and make sure the crushing force is applied evenly.

In a "bale" crusher, another set of pistons pushes another crushing plate in a lateral direction. Once the car has been crushed flat, it's crushed sideways, forming a "hay bale" of compacted car. Some baler crushers use specially shaped "claws" that fold the cars into bales or square logs. You can view this diagram showing how this works.

Advertisement

In addition, an oil reclamation system sits below the crushing bed. When motor oil and other fluids drain from the crushed car, they run down into this system where they are collected and stored for later recycling.