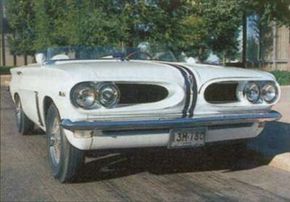

In the space between the orthodoxy of the Ford Falcon and the nontraditionalism of the Chevrolet Corvair, Pontiac staked out its own territory when it created the compact 1961-1963 Pontiac Tempest.

With the established success of the Volkswagen in America and the economic recession of 1958, the Big Three American carmakers began thinking beyond the credo of "longer, lower, wider" to develop compact cars to meet the demands of this burgeoning market. While Ford's answer to the call, the 1960 Falcon, was the runaway success in sales, Chrysler's Valiant was also very popular, owing to its European-influenced styling and sturdy Slant Six engine. Even Studebaker and AMC were in the game, and had been before any of the Big Three brought their downsized vehicles to market.

Advertisement

General Motors offered the most diverse line of compact cars, from the radical, rear-engined 1960 Corvair to the completely conventional Chevy II that debuted two years later. In between these two Chevrolets, in terms of chronology and technology, were the "B-O-P" compacts: Buick Special, Oldsmobile F-85, and Pontiac Tempest.

The fraternal triplets were based on a 112-inch-wheelbase platform featuring unitized construction and the same basic Fisher body. Mechanically, though, there were significant differences between them. Without a doubt, the Tempest featured the most unusual drivetrain of the trio, one of the most technologically advanced systems offered in an American car up to that time.

The story behind the development of the Tempest is one of divisional defiance and cost-conscious innovation. Perhaps the strongest motivation for its development was the Corvair, or more specifically, Pontiac's desire to not get a badge-engineered version of it.

Corporate management was looking to extend the platform's reach into other divisions, increasing sales volume to offset the development costs of the unique rear-engined compact. Pontiac, being next up the ladder from Chevrolet in the GM lineup, was the most logical choice, but Oldsmobile and Buick were under consideration for their own versions as well.

Pontiac's general manager at the time, Semon E. "Bunkie" Knudsen, did not want a tarted-up Corvair (to be named Polaris) as a Pontiac. In a 1994 interview with Thomas A. DeMauro, then-technical editor for High Performance Pontiac magazine, Knudsen explained why: "'First, if a dealer tells people that this is a new, more-advanced design, then how will the salesman justify the traditional drivetrain layouts found in Pontiac's other lines? Second, the Corvair is a rear-engine, air-cooled car. How do I make it different? There is no grille to be restyled and the engine can't be exchanged for a Pontiac powerplant. Therefore, how do I justify the extra $500 to $1,000 added to the price to sell it with a Pontiac nameplate?'"

Though Pontiac knew what they did not want to do, they needed to pick a direction for their new compact car. On the next page, learn how John Z. DeLorean helped shape the Pontiac Tempest.

For more information on cars, see:

- Classic Cars

- Muscle Cars

- Sports Cars

- New Car Search

- Used Car Search

Advertisement