Tire Maintenance System and AIRGO

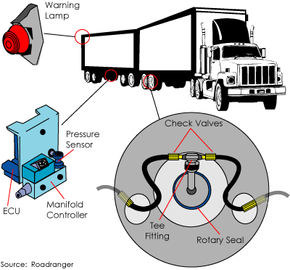

Dana Corporation's Tire Maintenance System (TMS) is a "smart" system for tractor trailers that monitors tire pressure and inflates tires as necessary to keep pressure at the right level. It uses air from the trailer's brake supply tank to inflate the tires.

The system has three main components:

Advertisement

- The tire hose assembly provides the air route to inflate the tire and has check valves so that the air lines and seals do not have to be pressurized when the system is not checking or inflating the tires. This cuts down on wear and tear on the seals.

- The rotary joint is comprised of air and oil seals and bearings and connects the air hose from the non-rotating axle to the rotating hubcap. Its air seals prevent leakage, and the oil seal prevents contamination. The rotary hub also has a vent to release air pressure in the hubcap.

- The manifold houses the pressure protection valve, which makes sure the system doesn't pull air if the brakes' air supply is below 80 psi. It also houses an inlet filter to keep the air clean, a pressure sensor to measure tire pressures and solenoids that control airflow to the tires.

Like the CTIS, this system also has an electronic control unit that runs the entire system. It performs checks to make sure the system is operational, notifies the driver via a warning light on the trailer (visible through the rear-view mirror) if a tire's pressure drops more than 10 percent below its normal pressure and performs system diagnostics.

The system performs an initial pressure check and adds air to any tire that needs it. The check valves in each tire hose ensure that the other tires don't lose pressure while one tire is being inflated. After an initial pressure check, the system depressurizes to relieve pressure from the seals. Every 10 minutes, the system pressurizes the lines and rechecks tire pressures.

The system measures tire pressure using a series of air pulses in the air lines. If the target pressure in the line is not reached after a certain amount of time, the system begins inflating the tire(s) until the correct pressure is reached.

AIRGO System

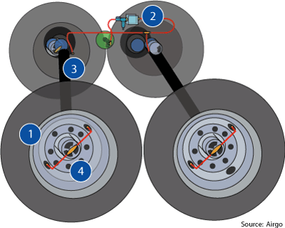

The AIRGO system is a constant monitoring system that uses a series of check valves to detect a loss in air pressure.

Unlike some of the other systems, AIRGO doesn't use air from the vehicle's braking system. When air seepage has occurred at any of various points in the system (1), the system draws air (2) from the vehicle's pneumatic system (not shown) and sends it by way of the vehicle's axles (3) -- through the axles themselves if they're pressurized or by way of tubing if they're not -- through the hubcap assembly (4) and into the tire requiring inflation.

A warning light, located on the trailer but visible through the driver's rearview mirror, illuminates when the system has inflated a tire.

Since this is a constant monitoring system, which puts a lot of wear and tear on the seals, AIRGO uses carbon-graphite and case-hardened steel for its seals rather than rubber.