Key Takeaways

- Diesel fuel is injected directly into the cylinder, unlike gas engines where fuel is injected outside the cylinder before the intake stroke.

- The injector in a diesel engine is crucial, as it must handle high pressure and heat while distributing fuel evenly in a fine mist.

- Some diesel engines use induction valves or pre-combustion chambers to swirl air for even fuel distribution, and they may use glow plugs to maintain high air temperature for ignition in cold weather.

A diesel fuel injection system differs from a gas engine in that the diesel fuel gets injected directly into the cylinder. In a gas engine, a port injection or a carburetor is used to inject fuel prior to the intake stroke (outside the cylinder) where the fuel mixes with air before it enters the cylinder.

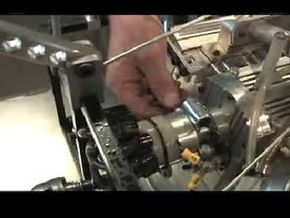

The injector on a diesel engine is its most complex part. The pressure and heat within a cylinder are quite intense and the injector has to be able to handle those conditions while still distributing the fuel in a fine mist. Equally important, the mist needs to be distributed evenly throughout the cylinder. Some diesel engines use induction valves, pre-combustion chambers or another type of device to swirl air through the combustion chamber. This process helps distribute the fuel mist evenly and keeps the ignition and combustion process smooth.

Advertisement

Some diesel engines help the combustion process by using a glow plug, or some other device that helps keep the air temperature in the cylinder at a sufficiently high temperature. If the air temperature is too low, the fuel won't ignite. When the engine isn't running, it obviously gets colder; as a result, a glow plug (which looks like heated coils, like on a toaster) is needed to heat the air when the car is started. By keeping the air temperature high, the engine has a better chance of starting in cold weather.