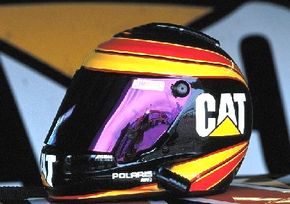

The Helmet

The head is probably the most vulnerable part of the human body during an accident. While the driver's body is strapped in very tightly, the head can jerk around uncontrollably. The helmet is designed to dissipate impact energy over the entire helmet and prevent debris from puncturing it.

Every NASCAR driver is required to wear some type of helmet. Most wear a full-face helmet, which covers the entire head and wraps around the mouth and chin. Others wear an open-face helmet, which only covers the head. Drivers who wear the open-face helmet usually wear protective goggles. They claim that a full-face helmet restricts their peripheral vision.

Advertisement

According to helmet manufacturer Simpson Race Products, there are three parts to their racing helmets:

- Outer shell

- BeadALL liner

- Inner liner, padding and hardware

Once a shell design has been approved, a custom-made nickel model is created for that particular helmet. Construction of the outer shell begins with a thin layer of gelcoat. Then a special resin, consisting of several types of glass, carbon, Kevlar and other exotic fibers and weaves, is added to the shell. This all combines to make the hard, glossy outer shell.

Just underneath the outer shell is the BeadALL liner, which is a special foam layer in the crown of the helmet. The purpose of this liner is to absorb the energy that the outer shell has not absorbed. This layer is made of polystyrene or polypropylene.

The inner liner of most helmets is a form-fitting layer that is made of either nylon or Nomex. Nomex is a special fire-retardant material made by DuPont. It doesn't melt, drip, burn or support combustion. Helmets are also equipped with cheek pads, chin straps and visors. The visor is made of a tough Lexan plastic. Lexan, which is also used in NASCAR windshields, is commonly known for its use in bulletproof glass.

All helmets go through some sort of testing before they are considered safe enough for high-speed racing. Snell Memorial Foundation is an independent organization that sets voluntary standards for auto-racing helmets. To test the impact resistance of a racing helmet, Snell places the helmet onto a metal head form and drops it onto various types of anvils. If the peak acceleration impacting the metal head exceeds a magnitude of force equal to 300 Gs, or 300 times the force of gravity, it is rejected. This level of impact is hard to conceptualize -- a head-on impact at 30 mph (48 kph) into a concrete wall is measured at 80 Gs. Most impacts on a race track are between 50 and 100 Gs. A 100-G impact for a 160-pound (72-kg) man would feel like 16,000 pounds (7,257 kg) pressing on top of him.

Another piece of driver-safety equipment is called the HANS device. This one is still being debated. In the next section, you'll learn what a HANS device is and what the controversy is about.