Connectors

Connectors are critical to today's cars. Without them, it would be nearly impossible to build or service a car. Whenever a bundle of wires passes through or attaches to a component of the car that might have to be removed, there must be a connector there to allow for that removal. A single connector can have more than 100 wires.

In the past, unreliable connectors have been the source of many electrical problems. Connectors have to be waterproof (modern connectors have several seals to keep out moisture), corrosion proof and provide good electrical contact for the life of the vehicle.

Advertisement

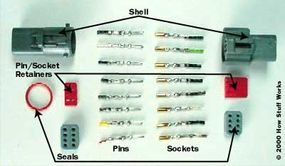

The connector pictured below is an eight-terminal connector -- it connects eight wires to each other.

To make this connection, there are a total of 23 separate parts. The main parts are:

- The shell

- The pins and sockets

- The pin retainer

- The seals

The Shell

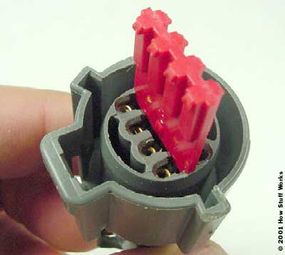

The shell is an intricate piece that has a complicated shape. There is a locking clip on the outside that holds the two halves of the connector together. There are holes for the pins, and there are special barbs that lock the pins in place once they are inserted. There are numerous grooves to hold seals and make sure things fit together tightly. All of these features are molded into the piece when it is made.

The Pins and Sockets

The pins and sockets are responsible for conducting electricity from one half of the connector to the other. These are made very precisely so that the pins and sockets fit together with just enough force to ensure a good connection, but not enough force to make connecting and disconnecting too difficult.

The pins are crimped to the wires using a special crimping tool. Part of the pin wraps around the bare wire, while another part clamps onto the insulation. This makes it harder to pull the wire away from the pin.

The Pin/Socket Retainer

The pin/socket retainer is a piece of plastic that slides into the connector from the front. It wedges against all of the plastic locking barbs so they can't release. This piece makes it nearly impossible for the pins and sockets to work their way loose.

The Seals

The seals prevent water from entering the connection once the connectors are locked together. Each connector has a rubber seal through which all of the wires are fed. This seal fits firmly into the back of the connector. One side of each connector has a round seal that keeps water from entering the space between the connectors once they are locked together.

For more information on wires, fuses, connectors and related topics, check out the links below.

Related HowStuffWorks Articles

More Great Links

- Introduction to Electricity - illustrated

- DC Circuits and Components

- Smart Continuity Tester

- Autoweb: Owning and Maintaining Your Vehicle

- GM Goodwrench Videos