At the heart of every combustion engine lies the camshaft, a component whose role is crucial yet often understated. It's essential to recognize that this piece of engineering genius directly influences an engine's performance and efficiency.

The camshaft's primary function is to regulate the opening and closing of the engine's intake and exhaust valves. It does so through a synchronized dance of rotation and timing. As the camshaft rotates, each camshaft lobe—a meticulously designed protrusion—interacts with valve lifters or pushrods to precisely control the timing and duration that valves stay open. This harmonious operation ensures that fuel can enter the combustion chamber and exhaust can exit at the optimum moments, directly impacting the engine's power output and fuel economy.

The role of the camshaft in a combustion engine cannot be overstated. By dictating the timing of the valve openings, it plays a pivotal part in the engine's breathing process. The efficiency of this process is what allows a vehicle to glide effortlessly on the road or roar to life with power.

The innovation behind each camshaft lobe's design and the precision with which the camshaft rotates underscore the complexity of modern automotive engineering. These components work tirelessly and unseen, yet they are fundamental to the engine's capability to harness energy from fuel.

Now that you have an understanding of the camshaft's function, it's important to know how they work. Let's start with the basics.

Camshaft Basics

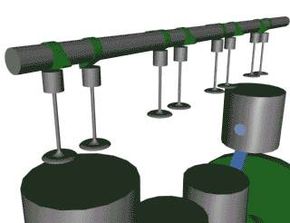

The key parts of any camshaft are the lobes. As the camshaft spins, the lobes open and close the intake and exhaust valves in time with the motion of the piston. It turns out that there is a direct relationship between the shape of the cam lobes and the way the engine performs in different speed ranges.

To understand why this is the case, imagine that we are running an engine extremely slowly -- at just 10 or 20 revolutions per minute (RPM) -- so that it takes the piston a couple of seconds to complete a cycle. It would be impossible to actually run a normal engine this slowly, but let's imagine that we could. At this slow speed, we would want cam lobes shaped so that:

- Just as the piston starts moving downward in the intake stroke (called top dead center, or TDC), the intake valve would open. The intake valve would close right as the piston bottoms out.

- The exhaust valve would open right as the piston bottoms out (called bottom dead center, or BDC) at the end of the combustion stroke, and would close as the piston completes the exhaust stroke.

This setup would work really well for the engine as long as it ran at this very slow speed. But what happens if you increase the RPM? Let's find out.

When you increase the RPM, the 10 to 20 RPM configuration for the camshaft does not work well. If the engine is running at 4,000 RPM, the valves are opening and closing 2,000 times every minute, or 33 times every second. At these speeds, the piston is moving very quickly, so the air/fuel mixture rushing into the cylinder is moving very quickly as well.

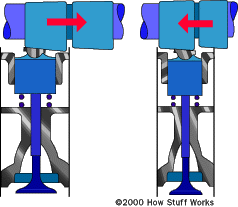

When the intake valve opens and the piston starts its intake stroke, the air/fuel mixture in the intake runner starts to accelerate into the cylinder. By the time the piston reaches the bottom of its intake stroke, the air/fuel is moving at a pretty high speed. If we were to slam the intake valve shut, all of that air/fuel would come to a stop and not enter the cylinder. By leaving the intake valve open a little longer, the momentum of the fast-moving air/fuel continues to force air/fuel into the cylinder as the piston starts its compression stroke. So the faster the engine goes, the faster the air/fuel moves, and the longer we want the intake valve to stay open. We also want the valve to open wider at higher speeds -- this parameter, called valve lift, is governed by the cam lobe profile.

The animation below shows how a regular cam and a performance cam have different valve timing. Notice that the exhaust (red circle) and intake (blue circle) cycles overlap a lot more on the performance cam. Because of this, cars with this type of cam tend to run very roughly at idle.

Any given camshaft will be perfect only at one engine speed. At every other engine speed, the engine won't perform to its full potential. A fixed camshaft is, therefore, always a compromise. This is why carmakers have developed schemes to vary the cam profile as the engine speed changes.

There are several different arrangements of camshafts on engines. We'll talk about some of the most common ones. You've probably heard the terminology:

- Single overhead cam (SOHC)

- Double overhead cam (DOHC)

- Pushrod

In the next section, we'll look at each of these configurations.