Discussions about energy independence, renewable energy and the dangers of carbon emissions have become a huge part of the political discourse in the United States. Everyone from the president to the guy holding the "no war for oil" sign at a public protest seems interested in ways to find alternatives to fossil fuels. But not all substitutes are created equal. Some are better for the environment; some are not. Some are renewable sources of energy; some are not. Synthetic fuels, aka synfuels, are just one of the many solutions on the table for solving the developing energy crisis.

In this case, though, the term "synthetic" can be misleading. It doesn't necessarily mean the fuels are unnatural or artificial. The U.S. Energy Information Administration defines a synthetic fuel as any fuel "produced from coal, natural gas or biomass feedstocks through chemical conversion" [source: U.S. Energy Information Administration]. That conversion creates substances that are chemically the same as crude oil or processed fuels, but were synthesized through artificial means. Conventional crude oil occurs naturally in the environment, and is used to produce a variety of fuels like gasoline and diesel. Synthetic fuel feedstocks, the raw materials used to make synfuels, have to be subjected to intense chemical and physical changes to be usable as crude oil or processed fuel.

Advertisement

The history of synfuels goes back further than you might think, although research and development have peaked in recent years. Synfuels were first researched in Germany in the 1923, when two scientists developed a process called the Fischer-Tropsch reaction. The process, which they named for themselves, involves converting gas into liquid fuels. While there are alternatives to the Fischer-Tropsch process, it is the most extensively tested and widely used method for creating synfuels today.

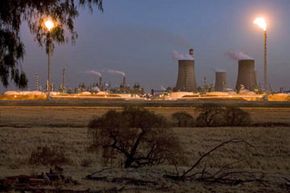

Historically, synfuels were first used extensively to fuel military vehicles in World War II Germany. Limited oil reserves among the Axis powers made synthetic options a necessary alternative [source: Becker]. In the 1970s, synfuels were researched heavily in the United States in the midst of widespread oil shortages. That research eventually dropped off, but has seen another spike recently, as concerns about energy independence and sustainability have become important political talking points. Other countries have used synfuels more extensively. For example, in South Africa, synfuels made from coal and natural gas have been an important part of the oil economy for 30 years.

To find out about the different types of synfuels and how each is produced, read on.

Advertisement